Stainless Steel High Shear CE Certificated European Standard Nail Polish Making Emulsifying Mixer

Introduction:

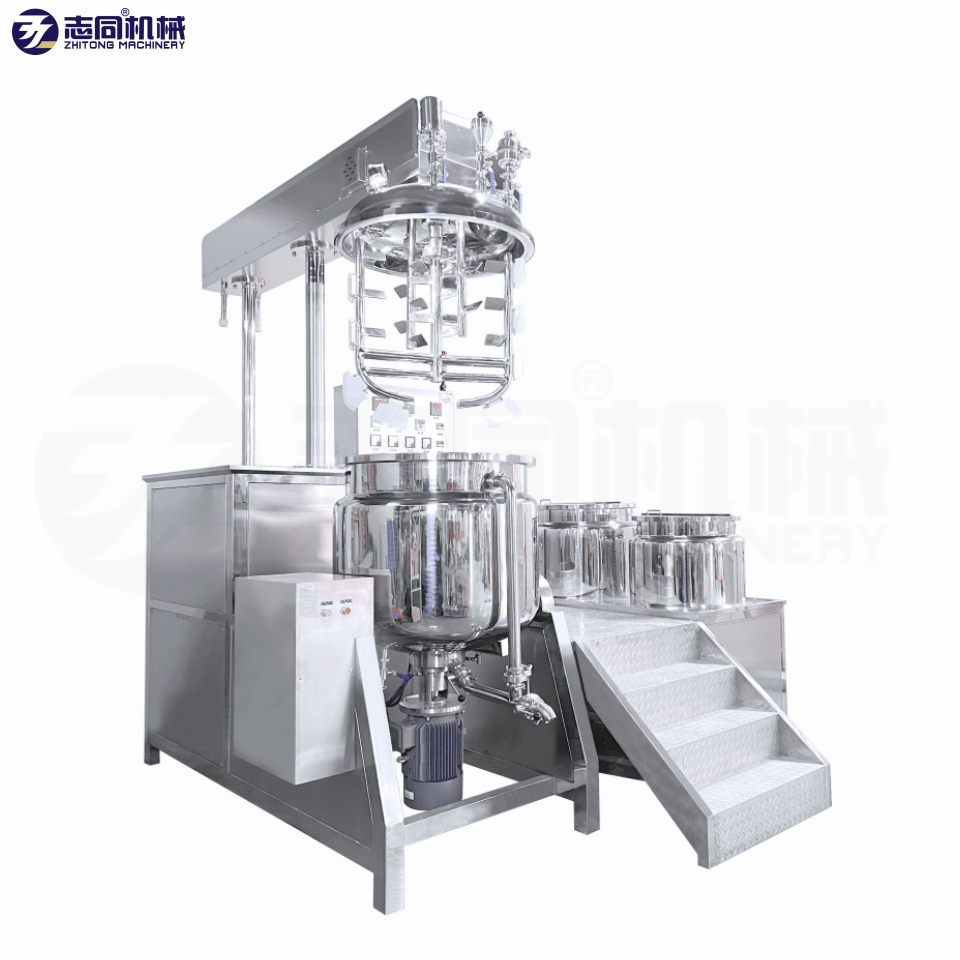

The vacuum emulsifying mixer is mainly composed of water pot, oil pot, emulsifying pot, vacuum system, lifting system(optional), electric control system(PLC is optional), operation platform. etc. The vacuum emulsifiers produced by our company include many varieties. The homogenizer systems include upper homogenization, lower homogenization, internal and external circulating homogenization. The mixing systems include single-way mixing, double-way mixing and helical mixing. The lifting systems include single-cylinder lifting and double-cylinder lifting. Various high quality products can be customized according to customers' requirements.

Technical Parameter:

Model: 10L

Homogenizer motor: 0.75KW 0-3000r/min

Agitator: 0.37KW 0-63r/min

Outside dimension: L 1350mm * W 580mm * H 1200/1800mm

Total power: steam heating 3KW; electric heating 6KW

Limit vacuum: -0.09mpa

Performances And Features:

▲ The vacuum emulsifiers produced by our company include many varieties. The homogenizing systems include upper homogenization, lower homogenization, internal and external circulating homogenization. The mixing systems include single-way mixing, double-way mixing and helical mixing. The lifting systems include single-cylinder and double-cylinder lifting. Various high quality products can be customized according to customers’ requirements;

▲ The triple mixing adopts the imported frequency converter for speed adjustment, which can meet different technological demands;

▲ The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 4,200rpm and the highest shearing fineness can reach 0.2-5μm;

▲ The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking is adopted, and especially for the powder materials, vacuum sucking can avoid dust;

▲ The emulsifying pot lid can adopt lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge;

▲ The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing, which fully confirms to GMP requirements;

▲ According to technological requirements, the tank body can heat and cool materials. The heating modes mainly includes steam heating and electric heating;

▲ To ensure the control of the whole machine is more stable, the electric appliances adopt imported configurations, so as to fully meet the international standards.

Details:

|

◉Tank cover with all function ports:

|

||

|

Vacuum pressure gauge and valve: to set the vacuum data and control on and off. |

Material Inlet: to suck the material from the other tank to the main tank via the pipe |

Viewing light: To facilitate the observation of the inside tank work. |

|

Spice inlet: To add the spice or small amount material. |

Air filter: To avoid outside air into the tank during the working condition. |

Sight glass and manhole: Be used to observe inside the pot condition. |

|

Cleaning system: Connect the 360° rotated cleaning ball. |

||

Detailed Description of Machine:

-

Fixed type vacuum homogenizer mixer machine ski...

-

Hydraulic lifting vacuum emulsifier mixing mach...

-

Key bottom mixer emulsifier for cosmetic making...

-

Vacuum Homogenizer Emulsifier|Cosmetic Homogeni...

-

Combine Customize homogenizer Mixer tank indus...

-

Electrical heating vacuum emulsifying equipmen...