Kanema

1. Siemens kukhudza PLC opaleshoni dongosolo

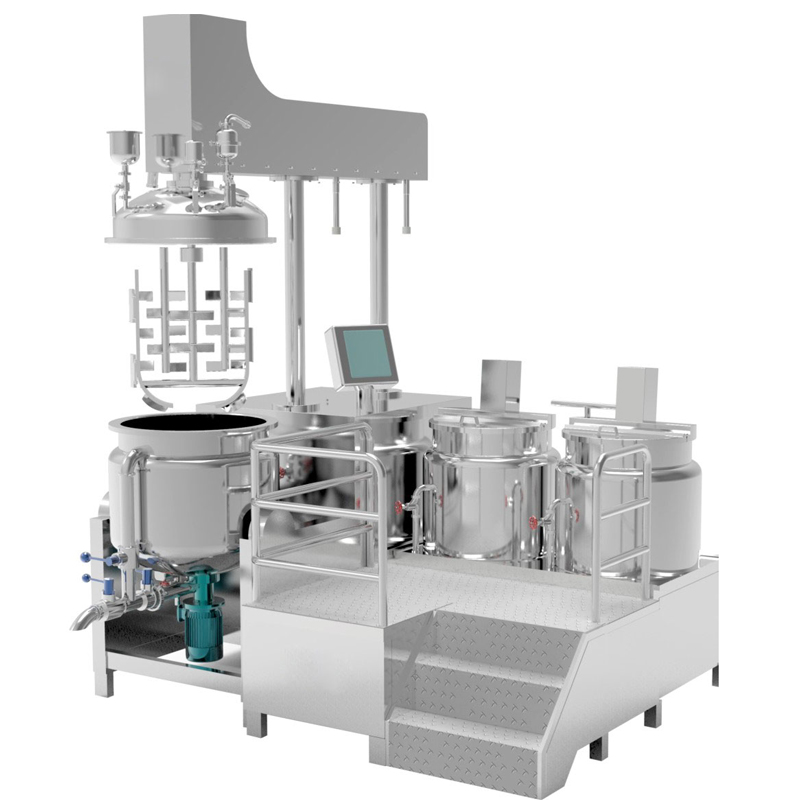

2.matanki zinthu.wosanjikiza wamkati SS 316. Pakati ndi kunja wosanjikiza SS304

Mtundu wa 3.Motor: AAB OR Siemens

4.Kutentha njira : kutentha kwa nthunzi kapena kutentha kwa magetsi kapena kusatenthetsa

5.magetsi: magawo atatu 220voltage 380voltage 460voltage 50HZ 60HZ kuti asankhe

6.nthawi ya mtsogoleri masiku 30

7. Kutsatira malamulo a GMP

8. Madzi ozizira amatha kuyikidwa mu interlayer kuti aziziritsa thanki kuti zinthu zizizizira

9. Homogenizer mukubwadamuka ndi tsamba agitator angagwiritsidwe ntchito padera kapena nthawi imodzi kwa lalikulu osiyanasiyana ndondomeko ndondomeko kusiyana

10.Raw Material tinthu, emulsification, kusakaniza, kusanja, kubalalitsidwa akhoza anamaliza quicky kuchepetsa mtanda nthawi zambiri mankhwala kupanga.

11.Frequency kutembenuka liwiro malamulo chipangizo akhoza kupanga liwiro kulamulira malinga ndi ndondomeko.

12.Kutulutsa kwakunja kwa vacuum homogenizing emulsifier ndi makina apamwamba kwambiri omwe angopangidwa kumene.

13.Under status vacuum.zinthu sizingakhudze mpweya .onetsetsani kuti chinthucho chili bwino

14.the homogeneous emulsification mode pansi pa kufalitsidwa kwakunja kungapangitse gawo lomwazika kukhala emulsified kwakanthawi kochepa, ndikusakanikirana bwino bwino.

15. kuzungulira ndi kutulutsa kofanana, kungathenso kukhala mphika waukulu kuphatikiza kutulutsa zabwino, zosavuta komanso zachangu.

16. yosavuta ntchito ndi ntchito, emulsifying ndi homogenizing kwenikweni bwino

17.Solids ndi zakumwa zitha kuwonjezeredwa mwachindunji kumutu wa emulsification komanso mwachangu

18.Magawo a emulsification ndi kubalalitsidwa amawonjezedwa mwachindunji kumutu wogwira ntchito.

19.Kuzungulira kwazinthu, kuyeretsa CIP, palibe mapampu owonjezera omwe amafunikira kuti atuluke.

20.Better processing zotsatira, lalifupi processing nthawi.

21. Vacuum emulsifying poto idapangidwa ndi vacuum system kuti ipope zinthu zamadzi ndi mafuta kupita ku mphika waukulu, ndikuchotsa thovu pakukonza.

22. Makina opangira magetsi amatha kutentha kapena kuziziritsa jekete munjira zosiyanasiyana zopanga.Kutentha kwa nthunzi ndi njira.

23. Pawiri malangizo kusakaniza ndi mkulu kukameta ubweya homogenizer kuonetsetsa emulsiyfing ndi kusanganikirana kwambiri wogawana ndi mogwira mtima ndi quicly .Ndiwoyenera kupanga zodzoladzola zida.

24. Akhoza kusakaniza ndi kumwazikana mowoneka bwino, olimba ndi Chinsinsi

25.. Mitundu yosiyanasiyana ya zinthu zopangira zidzasungunuka zomwe zili monga AES, AESA LSA.

26. Pakukonza, sungani kugwiritsa ntchito mphamvu ndikufupikitsa nthawi ya batch

27.zosavuta kupanga ndikuwonetsetsa kuti zikuyenda mosavuta, ndipo makina onse amapulumutsa malo potengera kutalika kwa msonkhano.

28. PLC touch screen controller kupanga makina osavuta kugwiritsa ntchito komanso njira zonse zodziwikiratu.

29. The homogenizer imagwiranso ntchito ngati mpope kutengerapo potulutsa zomalizidwa kupulumutsa mphamvu yamunthu

30.Variable liwiro la homogenizer1-3000R/mphindi ndi agitator 1-63R/mphindi;

Zofunikira zaukadaulo:

| Chitsanzo | Kuthekera(L) | Emulsify injini | Kusakaniza motere | Mphamvu yamagetsi(kutentha kwa nthunzi/magetsi) | Vacuum yochepa (Mpa) | Kukula (mm)L*W*H | ||||

| Mndi pot | Mphika wa mafuta | Mphika wamadzi | KW | RPM | KW | RPM | ||||

| 100 | 100 | 50 | 80 | 4 | 0-3000 | 1.5 | 0-63 | 10/37 | -0.095 | 2385 * 2600 * 200-2900 |

| 200 | 200 | 100 | 160 | 5.5 | 2.2 | 12/40 | 2650*3000*2400-3100 | |||

| 500 | 500 | 250 | 400 | 11 | 4 | 18/63 | 2850*3000*3000 | |||

| 1000 | 1000 | 500 | 800 | 15 | 5.5 | 30/90 | 3000*3100*3000 | |||

| 2000 | 2000 | 1000 | 1600 | 18 | 7.5 | 40/120 | 3100*3100*3000 | |||

Njira

1.magetsi: magawo atatu: 220v 380v .415v.50HZ 60HZ;

2.Mphamvu: 100L mpaka 5000L;

3.Mtundu wamagalimoto: ABB.Siemens njira;

4.Njira yowotchera: Kutentha kwamagetsi ndi njira yowotchera nthunzi;

5.Control system plc kukhudza skrini.Mfungulo pansi;

6.Mtundu wosasunthika kapena mtundu wokwera wa Hydraulic kapena kukweza kwa Pneumatic;

7.mitundu yosiyanasiyana ya ma paddles amakwaniritsa zofunikira zosiyanasiyana;

8.SIP ikupezeka mukafunsidwa kuti muyeretsedwe.